The Cold Storage Industry

The cold storage industry is a vital component of the supply chain, providing temperature-controlled storage and transportation services for perishable goods. This industry is essential for preserving the quality and safety of products such as food, pharmaceuticals, and other temperature-sensitive items.

Cold Storage Industry Software

The cold storage industry is a vital component of the supply chain, providing temperature-controlled storage and transportation services for perishable goods. This industry is essential for preserving the quality and safety of products such as food, pharmaceuticals, and other temperature-sensitive items. THINK’s warehouse management system software was able to offer detailed and effective FIFO control using a number of criteria including ‘best before’ and ‘use by’ date. To meet food specific requirements such as the need to step out of FIFO and pick from later batches on demand where long distance shipping is required (all controlled by user permissions) THINK’s WMS had to support and be compliant with HACCP, can be configured to support product compliance. THINK has also worked with other prominent suppliers to the cold storage industry including Tesco and Bowman Stores, and XPO Logistics.

Benefits to The Cold Storage Industry

The benefits of implementing a warehouse management system within the cold storage industry include:

- Temperature control and monitoring

- Inventory visibility and accuracy

- Optimised storage and picking

- Compliance with regulations

- Traceability and Lot tracking

- Reduced product spoilage

- Real-time alerts and notifications

- Improved order accuracy

- Efficient cross-docking

- Labour efficiency

- Enhanced customer service

- Integration with other systems

chilled and frozen food storage centre

A large chilled and frozen food storage centre in the UK contacted THINK following a multi-million-pound investment to review their current warehouse software and processes for scalability which resulted in doubling the size of what was already a large scale facility.

Read the case study

Why Choose THINK?

We employ experienced WMS consultants to work with your company and assess the current warehouse operations, understand your specific needs and challenges, and then recommend, implement, and customise WMS solutions that align with the company’s goals and objectives. Our expertise covers a wide range of areas, including technology, logistics, supply chain management, process optimisation and software integration. When combined with our approach to project management, this leads to consistent achievement of objectives within agreed timescales.

From the outset our Warehouse Management System was designed to easily interface with other business applications ranging from ERP systems such as SAP, System 21, SAGE, MS Dynamics, Oracle etc. Through to Ecommerce providers such as Shopify and Prestashop.

Implementing a warehouse management system / WMS should not mean an upheaval on time or costs. THINK’s wealth of industry experience with a deep routed industry skill set means we can work with your business to provide the most intuitive WMS on the market. Get your staff trained and operational within 45 minutes – it really is that user friendly.

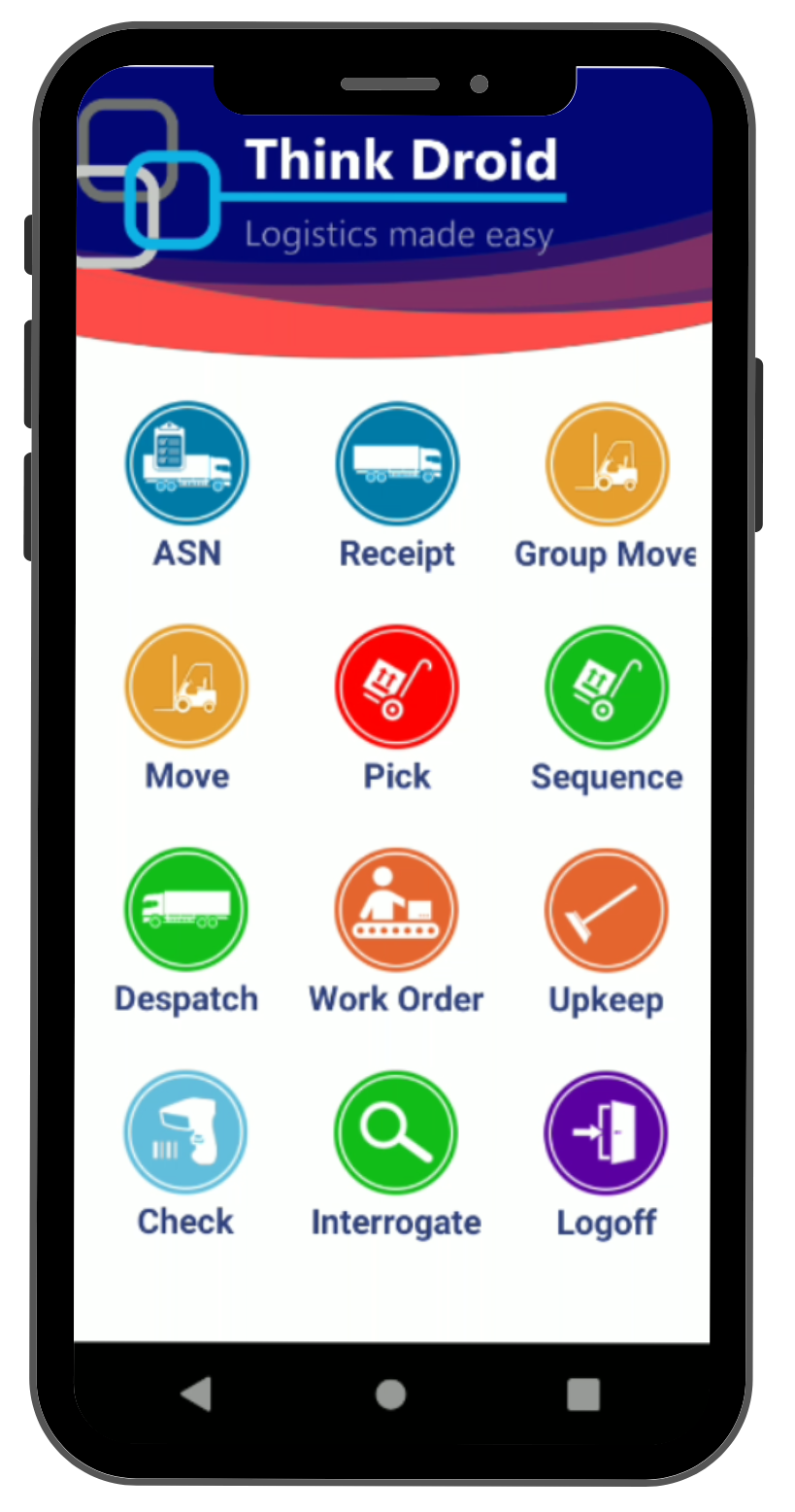

Here is an example of our system on an Android phone, showing how you can use it on the go.

Are you worried that a warehouse management solution will be too expensive, or that you will be trapped in a long contract? To arrange a demo or discuss your requirements contact THINK; give us a call on 0330 350 0715, email enquiries@tkinv.com or complete the enquiry form below. We can work with your business to help save you money and drive down costs.