Warehouse Management SystemS (WMS)

DESIGNED BY EXPERTS FOR PROFESSIONALS

At THINK Inventory Solutions, our Warehouse Management System is designed to easily interface with other business applications ranging from ERP systems such as SAP, System 21, SAGE, MS Dynamics, Oracle etc. Through to Ecommerce providers such as Shopify & Prestashop.

WE CONCENTRATE ON WHAT WE DO BEST, WAREHOUSE MANAGEMENT SYSTEMS (WMS)

Our Warehouse Management System had a unique birth. It was developed in the fast-moving automotive supply industry, which in itself may not be unique, but when combined with the method of development, a clearly unique and class-leading product was born.

WAREHOUSE MANAGEMENT SYSTEMS ARE EASY TO INTERFACE

From the outset our Warehouse Management System was designed to easily interface with other business applications ranging from ERP systems such as SAP, System 21, SAGE, MS Dynamics, Oracle etc. Through to Ecommerce providers such as Shopify and Prestashop. THINK Inventory Solutions can help you:

- Setup, organise, and align your processes

- Reduce your costs

- Increase inventory accuracy

- Provide real-time stock control

- Reduce paper based transactions

- Provide consultancy in all aspects of system and process design

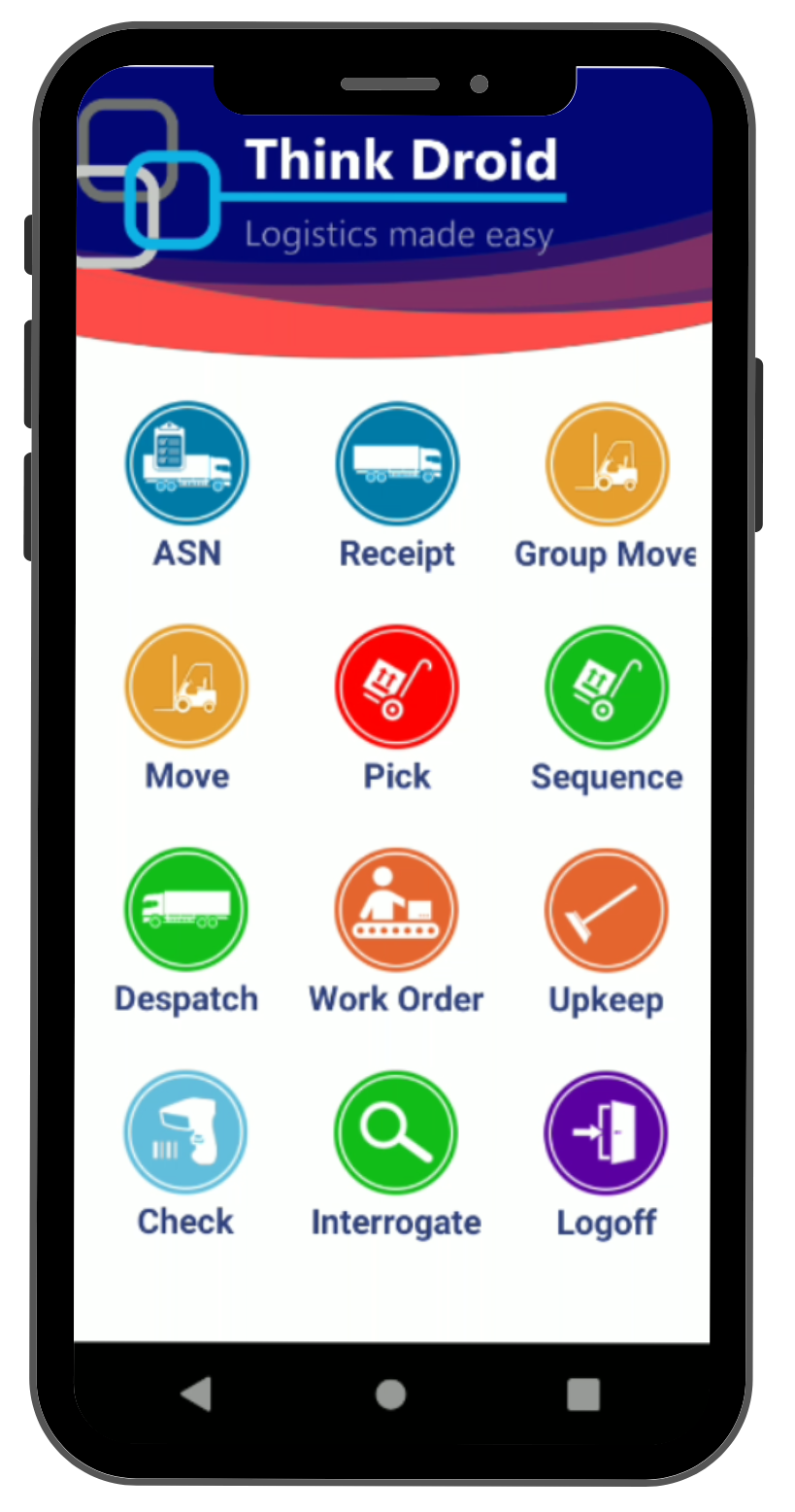

- Align with your android devices

Implementing a warehouse management system / WMS should not mean an upheaval on time or costs. THINK’s wealth of industry experience with a deep routed industry skill set means we can work with your business to provide the most intuitive WMS on the market. Get your staff trained and operational within 45 minutes – it really is that user friendly.

Here is an example of our system on an Android phone, showing how you can use it on the go.

Need a WMS? Download our Brochure

To find out more about the core functionality of THINK’S Warehouse Management System download our brochure.

INBOUND

The ability to start the inventory management process at the point of receipt. Read more about our Inbound Warehouse Management System.

LOCATE & MANAGE

Inbound stock control is a critical aspect of warehouse management that focuses on effectively managing and controlling inventory as it arrives at the warehouse, whilst ensuring efficient utilisation of available space. Read more about Locate & Manage Stock Management.

DEMAND FULFILLMENT

THINK’s warehouse management system fulfils customer orders efficiently and accurately based on demand signals received by the WMS. Read more about our Demand Fulfillment Functionality.

OUTBOUND

We help you provide your customers with real-time information on their shipments at the point of despatch. Read more about our Outbound Functionality.

CORE

THINK WMS provides full traceability for all transactions at handling unit level. Read more about our Core Functionality.

When a client made major internal changes to their systems, we upgraded our entire IT infrastructure so that our Warehouse Management System would synchronise with theirs. Think’s project manager Shaun worked with our client to ensure that every requirement was drafted, costed, tested and implemented within budget and timeframe. He ensured successful roll out and aftercare of the finished WMS system. Three months after implementation, THINK continue to be a huge support to HGS and are in contact regularly to help and offer advice. Their adaptable and scalable WMS system is essential to the smooth running of our 3PL operation.

Are you worried that a warehouse management solution will be too expensive, or that you will be trapped in a long contract? To arrange a demo or discuss your requirements contact THINK; give us a call on 0330 350 0715, email enquiries@tkinv.com or complete the enquiry form below. We can work with your business to help save you money and drive down costs.