The Automotive Industry

The automotive industry is a vast and multifaceted sector that encompasses the design, manufacturing, marketing, sale, and maintenance of motor vehicles. It is dynamic, and its evolution is shaped by technological advancements, consumer preferences, regulatory requirements, and global economic factors.

Suppliers to the Automotive Industry

THINK’s warehouse management system software provides AMCO real time tracking and feedback for inventory, giving visibility of productivity and negating the need for paper-based systems. THINK provides a suite of flexible management reporting, allowing AMCO’s management to identify improvement opportunities; and the electronic interfaces enable connectivity to a host of different formats. THINK has also worked with other prominent suppliers to the automotive and car parts industry including International Automotive Components (IAC), Grupo Antolin and Magna.

Benefits to the Automotive industry

The benefits of implementing a warehouse management system within the automotive industry include:

- Improved inventory accuracy

- Enhanced order accuracy

- Increased efficiency in order fulfilment

- Sequencing solutions

- Supplier collaboration

- Streamlined returns management.

- Increased traceability and compliance

- Real-Time Reporting and Analytics

- Optimised space utilisation

- Scalability for business growth

- Integration with other systems

- Increased customer satisfaction

International Automotive Components (IAC)

The International Automotive Components (IAC) Halewood site in Liverpool approached THINK following the successful WMS implantation at the companies Elmdon site in Birmingham. Originally warehousing and production were housed within one building, but IAC Halewood were looking to automate their manual replenishment process to provide a greater degree of control for how material is replenished from the warehouse to the assembly line. IAC required a robust process to ensure material stock levels were able to keep assembly on the shop floor moving.

Why Choose THINK?

We employ experienced WMS consultants to work with your company and assess the current warehouse operations, understand your specific needs and challenges, and then recommend, implement, and customise WMS solutions that align with the company’s goals and objectives. Our expertise covers a wide range of areas, including technology, logistics, supply chain management, process optimisation and software integration. When combined with our approach to project management, this leads to consistent achievement of objectives within agreed timescales.

From the outset our Warehouse Management System was designed to easily interface with other business applications ranging from ERP systems such as SAP, System 21, SAGE, MS Dynamics, Oracle etc. Through to Ecommerce providers such as Shopify and Prestashop.

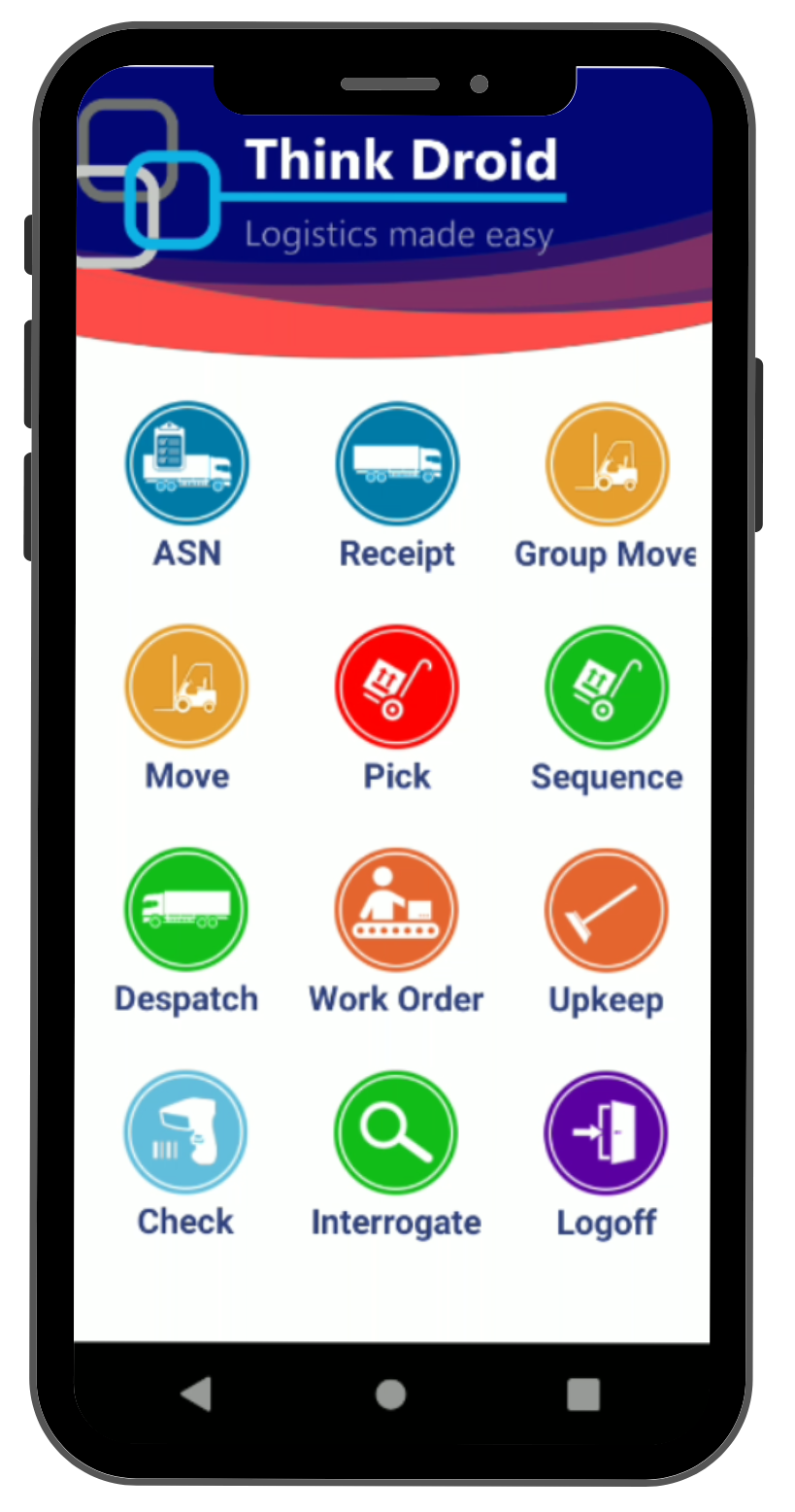

Implementing a warehouse management system / WMS should not mean an upheaval on time or costs. THINK’s wealth of industry experience with a deep routed industry skill set means we can work with your business to provide the most intuitive WMS on the market. Get your staff trained and operational within 45 minutes – it really is that user friendly.

Here is an example of our system on an Android phone, showing how you can use it on the go.

Are you worried that a warehouse management solution will be too expensive, or that you will be trapped in a long contract? To arrange a demo or discuss your requirements, give THINK a call on 0330 350 0715, email enquiries@tkinv.com or complete the Quick Quote form below. We can work with your business to help save you money and drive down costs.