The Food and Drink Industry

The food and drink industry, also known as the food and beverage industry, is a broad sector encompassing the production, processing, distribution, and sale of food and drink products. This industry is vital to the global economy, providing a wide array of goods that cater to various consumer preferences. The food and drink industry is dynamic, diverse, and essential to meeting the nutritional needs and culinary preferences of people worldwide. It continuously evolves to adapt to market trends, technological advancements, and societal changes.

Food and Drink Industry Software

THINK’s warehouse management system software was able to configure and read various label types for a drinks manufacturer seeking a 3PL solution for goods storage and fulfilment. Our WMS captured the relevant information and stored it against each pallet record. At the picking and despatch stage, this information could be relayed back to both the customer and the manufacturer. For picking, a strict FIFO methodology was adopted to ensure stock turnover. With shipments of palletised goods taking place to customers around the country using NFS Connect Transport Management System. THINK has also worked with other prominent suppliers to the food and drink industry including Tesco, Bowman Stores and Mars Drinks.

Benefits to the Food and Drink Industry

The benefits of implementing a warehouse management system within the food and drink industry include:

- Inventory accuracy

- Traceability and lot control

- Compliance with regulations

- Improved order accuracy

- Efficient Lot rotation and FIFO

- Temperature control and monitoring

- Optimised storage

- Real-time visibility

- Streamlined recall processes

- Reduction in operating costs

- Enhanced supplier and customer relationships

- Integration with other systems

chilled and frozen food storage centre

A large chilled and frozen food storage centre in the UK contacted THINK following a multi-million-pound investment to review their current warehouse software and processes for scalability which resulted in doubling the size of what was already a large scale facility.

Read the case study

SOFT DRINKS MANUFACTURER CASE STUDY

An established drinks manufacturer from the North East was seeking a 3PL solution for their finished product to include storage and fulfilment. We were faced with many branded soft drinks products, each with a unique pallet label. Most pallet labels from the manufacturer are Odette style, with embedded bar codes including a combination of Best Before Dates, Batch Numbers, Pallet SSCC code identifiers, bottle / can quantities, Part Numbers, and Expiry Dates.

Read the case study

Why Choose THINK?

We employ experienced WMS consultants to work with your company and assess the current warehouse operations, understand your specific needs and challenges, and then recommend, implement, and customise WMS solutions that align with the company’s goals and objectives. Our expertise covers a wide range of areas, including technology, logistics, supply chain management, process optimisation and software integration. When combined with our approach to project management, this leads to consistent achievement of objectives within agreed timescales.

From the outset our Warehouse Management System was designed to easily interface with other business applications ranging from ERP systems such as SAP, System 21, SAGE, MS Dynamics, Oracle etc. Through to Ecommerce providers such as Shopify and Prestashop.

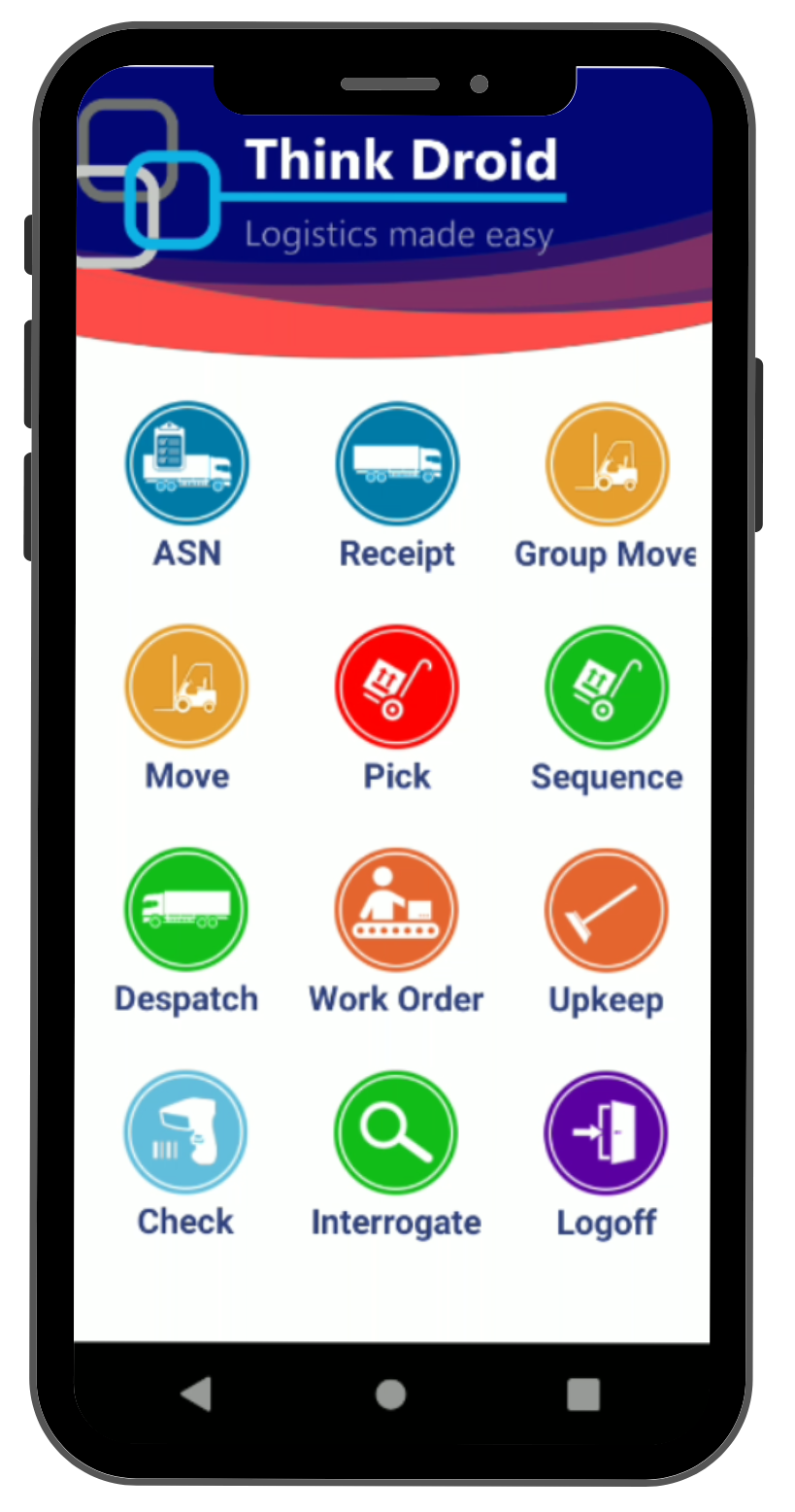

Implementing a warehouse management system / WMS should not mean an upheaval on time or costs. THINK’s wealth of industry experience with a deep routed industry skill set means we can work with your business to provide the most intuitive WMS on the market. Get your staff trained and operational within 45 minutes – it really is that user friendly.

Here is an example of our system on an Android phone, showing how you can use it on the go.

Are you worried that a warehouse management solution will be too expensive, or that you will be trapped in a long contract? To arrange a demo or discuss your requirements contact THINK; give us a call on 0330 350 0715, email enquiries@tkinv.com or complete the enquiry form below. We can work with your business to help save you money and drive down costs.