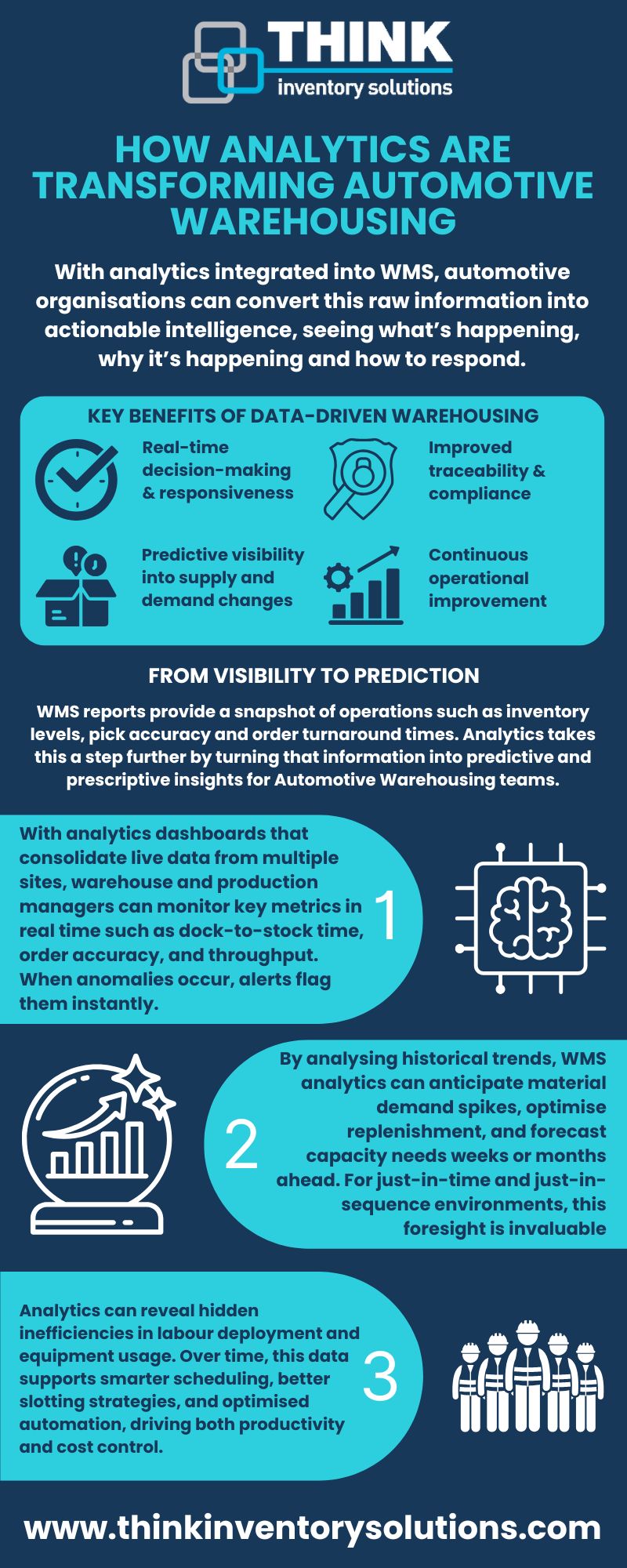

Modern Automotive Warehousing generates enormous amounts of operational data, covering inbound materials, storage, sequencing, and outbound logistics. Yet without analytics, that data remains underused. With analytics integrated into Warehouse Management Systems (WMS), automotive organisations can now convert this raw information into actionable intelligence, seeing not only what’s happening, but why it’s happening and how to respond.

Key benefits of data-driven Automotive Warehousing include:

- Real-time decision-making and responsiveness

- Predictive visibility into supply and demand changes

- Improved traceability and compliance

- Continuous operational improvement

From Visibility to Prediction: Analytics in Automotive Warehousing

WMS reports provide a snapshot of operations such as inventory levels, pick accuracy and order turnaround times. Analytics takes this a step further by turning that information into predictive and prescriptive insights for Automotive Warehousing teams.

- Real-Time Operational Intelligence for Automotive Warehousing

With analytics dashboards that consolidate live data from multiple sites, warehouse and production managers can monitor key metrics in real time such as dock-to-stock time, order accuracy, and throughput. When anomalies occur, alerts flag them instantly, preventing line stoppages or shipment delays before they happen.

- Predictive Planning and Demand Forecasting in Automotive Warehousing

By analysing historical trends, WMS analytics can anticipate material demand spikes, optimise replenishment, and forecast capacity needs weeks or months ahead. For just-in-time (JIT) and just-in-sequence (JIS) environments, this foresight is invaluable, it keeps the production line running smoothly, even when global conditions change.

- Intelligent Labour and Equipment Utilisation

Analytics can reveal hidden inefficiencies in labour deployment and equipment usage. Over time, this data supports smarter scheduling, better slotting strategies, and optimised automation, driving both productivity and cost control.

Data-Driven Reporting in Automotive Warehousing

Analytics turn traditional warehouse reporting into a strategic improvement tool, enabling teams to benchmark performance, identify root causes, and support compliance effortlessly. Standardized KPIs across multiple plants or regions allow for clear performance comparisons. Warehouse managers can pinpoint high-performing sites and replicate best practices across the network. When issues arise, like missed sequencing or shipment errors, reporting tools trace data upstream to reveal where breakdowns occurred. This allows for faster, more targeted resolutions. Automotive standards demand meticulous traceability. Automated WMS reporting ensures every component’s movement is recorded and accessible, reducing the time and cost of audit preparation.

Turning Analytics into Action in Automotive Warehousing

Analytics aren’t just about visibility; they drive measurable improvement. Companies adopting analytics-led Automotive Warehousing are achieving:

- 20% faster issue resolution through real-time data access

- Up to 25% fewer line-side shortages with predictive alerts

- Significant reporting time reductions through automation

- Improved delivery performance via actionable insight

These results translate into stronger customer satisfaction, leaner operations, and more resilient supply chains. As the automotive industry embraces electrification and digital transformation, analytics have become the foundation of smarter operations. By integrating advanced reporting and analytics into Automotive Warehousing, manufacturers and suppliers are not just managing inventory, they’re building resilience, agility, and intelligence across the entire supply chain. In today’s data-driven world, it’s not enough to move efficiently, you must drive smarter.

Are you worried that a warehouse management solution will be too expensive, or that you will be trapped in a long contract? To arrange a demo or discuss your requirements, give THINK a call on 0330 350 0715, email enquiries@tkinv.com or complete the Quick Quote form below. We can work with your business to help save you money and drive down costs.

Recent Comments