The THINK Warehouse Management System was developed in the automotive industry, so we know a thing or two about how to improve stock accuracy in automotive supply chains. Improving accuracy helps suppliers reduce errors, avoids costly stoppages, and strengthens relationships with OEMs – Original Equipment Manufacturers.

In the automotive industry, stock accuracy isn’t just about keeping shelves tidy, it’s about keeping production lines running. A single missing part can halt an entire line, costing thousands in downtime. Yet many automotive suppliers still rely on spreadsheets, paper processes, or disconnected systems to manage their warehouses. What surprises us about this is that some of these suppliers are:

Tier 1

Those who supply products or services directly to the OEM, so in automotive they may supply complete car seats, braking systems, or infotainment systems directly to the likes of Ford or Toyota.

Tier 2

Those who supply to Tier 1 suppliers, not directly to the OEM, so they may supply seat fabric or sensors to the Tier 1 seat manufacturer.

Why Stock Accuracy Matters in Automotive Warehousing

Automotive supply chains are unique because there are thousands of small components, each critical. There are strict delivery schedules, so Just-in-time (JIT) production leaves no room for error. The margins are tight so mistakes are costly and can damage supplier credibility. There are traceability requirements, and OEMs often require full visibility of batch and lot numbers. When stock data doesn’t match reality, suppliers risk line stoppages, penalty charges, rejected deliveries and lost contracts. Improving accuracy is therefore not just an operational need, it’s a competitive advantage.

If your business is in the automotive industry, and especially if you are a Tier 1 or Tier 2 supplier, we would love to hear from you. We have extensive experience in this industry and would love to discuss how we can help improve stock accuracy, as well as other challenges that you may be facing. The following is a short summary of discussion points.

- Replace Manual Processes with a Warehouse Management System (WMS)

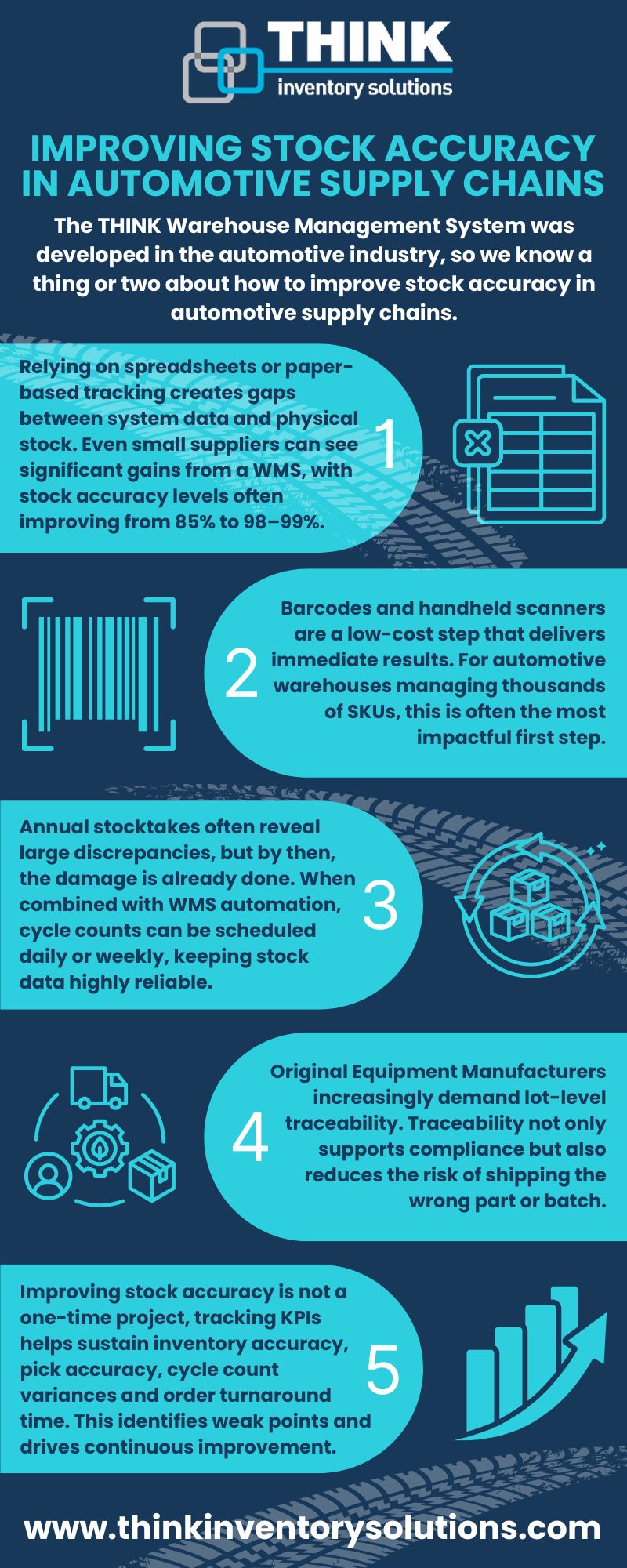

Relying on spreadsheets or paper-based tracking creates gaps between system data and physical stock. A Warehouse Management System (WMS) provides real-time visibility of inventory, barcode scanning to eliminate manual entry errors, automated cycle counting and integration with ERP and EDI systems. Even small suppliers can see significant gains from a WMS, with stock accuracy levels often improving from 85% to 98–99%.

- Adopt Barcode Scanning and Handheld Devices

Barcodes and handheld scanners are a low-cost step that delivers immediate results. Each movement (receiving, picking, dispatch) is recorded in real time, operators are guided through the process, reducing mistakes and inventory levels stay aligned with reality. For automotive warehouses managing thousands of SKUs, this is often the most impactful first step.

- Introduce Cycle Counting Instead of Annual Stocktakes

Annual stocktakes often reveal large discrepancies, but by then, the damage is already done. Cycle counting, so checking a subset of stock regularly, helps catch issues early. Benefits include continuous accuracy improvement, less disruption to operations and early detection of process gaps. When combined with WMS automation, cycle counts can be scheduled daily or weekly, keeping stock data highly reliable.

- Focus on Traceability and Batch Control

OEMs increasingly demand lot-level traceability. A WMS can automatically track stock by batch/lot/serial number, ensure FIFO (first in, first out) or FEFO (first expiry, first out) is applied and provide instant recall reports in case of quality issues. Traceability not only supports compliance but also reduces the risk of shipping the wrong part or batch.

- Monitor KPIs and Continuously Improve

Improving stock accuracy is not a one-time project and tracking KPIs helps sustain the following results: inventory accuracy % (system vs physical), pick accuracy % (correct items shipped), cycle count variances and order turnaround time. Regularly reviewing these metrics identifies weak points and drives continuous improvement.

THINK WMS for the Automotive Industry

In automotive supply chains, stock accuracy directly impacts production uptime, customer satisfaction, and profitability. By replacing manual processes with a WMS, adopting barcode scanning, implementing cycle counting, and focusing on traceability, suppliers can achieve near-perfect accuracy. For tier 1 and tier 2 suppliers, these improvements are more than operational efficiencies, they are critical to retaining and winning new OEM contracts. If you’d like to learn how a purpose-built WMS for automotive suppliers can boost accuracy and efficiency, get in touch with our team today.

You may be interested in these similar blog posts:

- Warehouse Sequencing for the Automotive Industry

- Implementing a Warehouse Management System into the Automotive Industry

- Accelerate Your Automotive Supply Chain with a Modern WMS from THINK

- The Importance of Just In Time (JIT) and Just In Sequence (JIS) for the Automotive Industry

- Automotive Inventory Management Solutions

Are you worried that a warehouse management solution will be too expensive, or that you will be trapped in a long contract? To arrange a demo or discuss your requirements contact THINK; give us a call on 0330 350 0715, email enquiries@tkinv.com or complete the enquiry form below. We can work with your business to help save you money and drive down costs.

Recent Comments