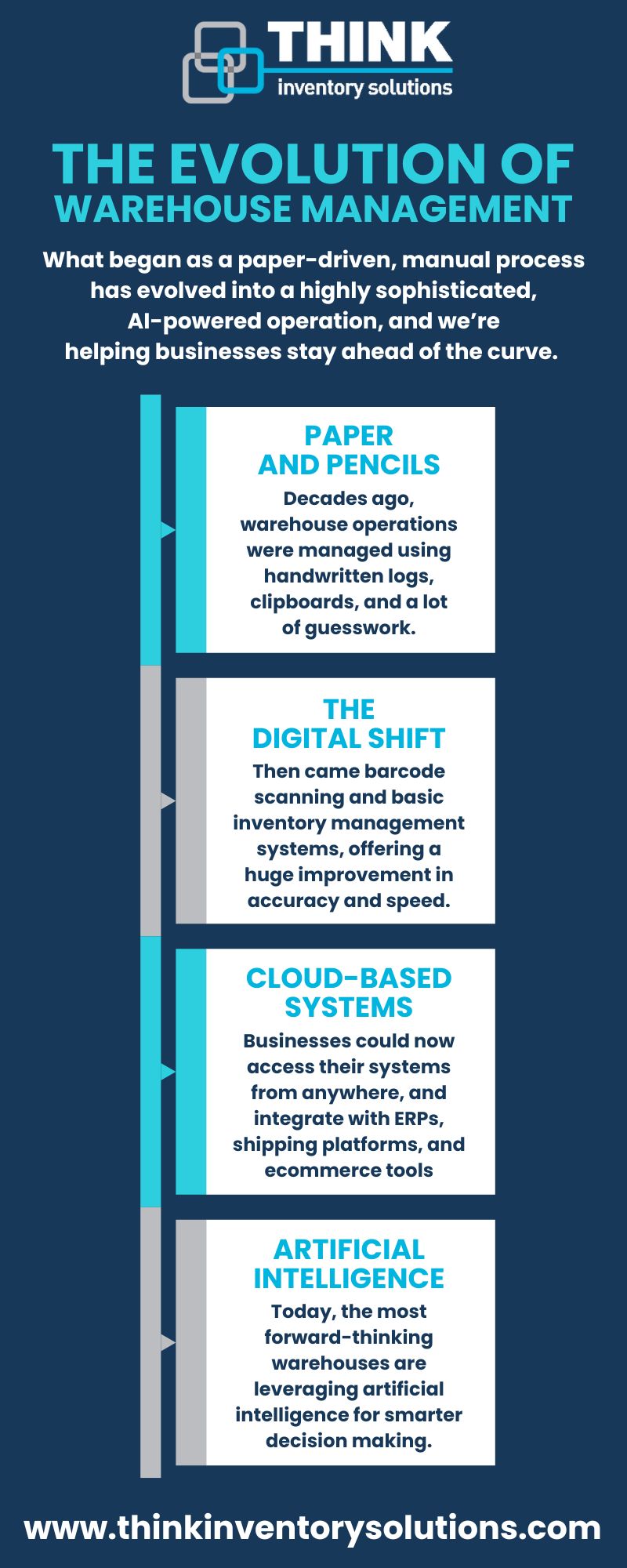

In the fast-paced world of supply chain and logistics, change is constantly happening. Nowhere is this more evident than in warehouse management. What began as a paper-driven, manual process has evolved into a highly sophisticated, AI-powered operation. Imagine a warehouse management system (WMS) that learns your sales trends, suggests stock re-orders before you run out, improves decision making through data insights, and dynamically adjusts warehouse layouts for seasonal efficiency. That’s not the future, it’s now. At THINK Inventory Solutions, we’ve seen this transformation up close and we’re helping businesses stay ahead of the curve.

Paper and Pencils: The Early Days

Decades ago, warehouse operations were managed using handwritten logs, clipboards, and a lot of guesswork. Inventory was tracked on spreadsheets, if it was tracked at all, and finding a lost item often meant hours of searching. These methods were prone to human error, inefficient, and lacked real-time visibility.

The Digital Shift: Barcodes and Basic Software

The first big leap came with barcode scanning and basic inventory management systems. These tools offered a huge improvement in accuracy and speed. Digital records replaced handwritten logs, and warehouses began to gain more control over stock levels, shipping accuracy, and space utilisation.

Cloud-Based Systems: Flexibility and Scale

As the internet evolved and grew, cloud-based WMS changed the game. Businesses could now access their systems from anywhere, scale operations quickly, and integrate with ERPs, shipping platforms, and ecommerce tools. At THINK Inventory Solutions, we have helped many clients transition to cloud WMS solutions and have brought visibility and coordination across their supply chains.

Enter AI: Intelligence Meets Automation

Today, the most forward-thinking warehouses are leveraging artificial intelligence. AI doesn’t just automate tasks; it makes smarter decisions. Machine learning algorithms can forecast demand, optimise picking routes, manage labour scheduling, and even predict equipment failures before they happen

Customer expectations are rising and so this transformation is more important than ever. Same-day delivery, real-time tracking, and personalised service are becoming the norm. To keep up, warehouses must be smarter, faster, and more adaptive than ever. That’s where THINK Inventory Solutions comes in. We don’t just implement systems; we help you transform your entire inventory operation. From selecting the right technology to streamlining your workflow and integrating with your existing tools, we’re here to make your warehouse work for your business, not the other way around. As AI continues to evolve, we expect to see even more automation from robotic picking systems to predictive analytics that eliminate inventory blind spots. And as always, we’ll be right there with our clients, guiding them into the next era of warehouse excellence.

Are you worried that a warehouse management solution will be too expensive, or that you will be trapped in a long contract? To arrange a demo or discuss your requirements contact THINK; give us a call on 0330 350 0715, email enquiries@tkinv.com or complete the enquiry form below. We can work with your business to help save you money and drive down costs.

Recent Comments