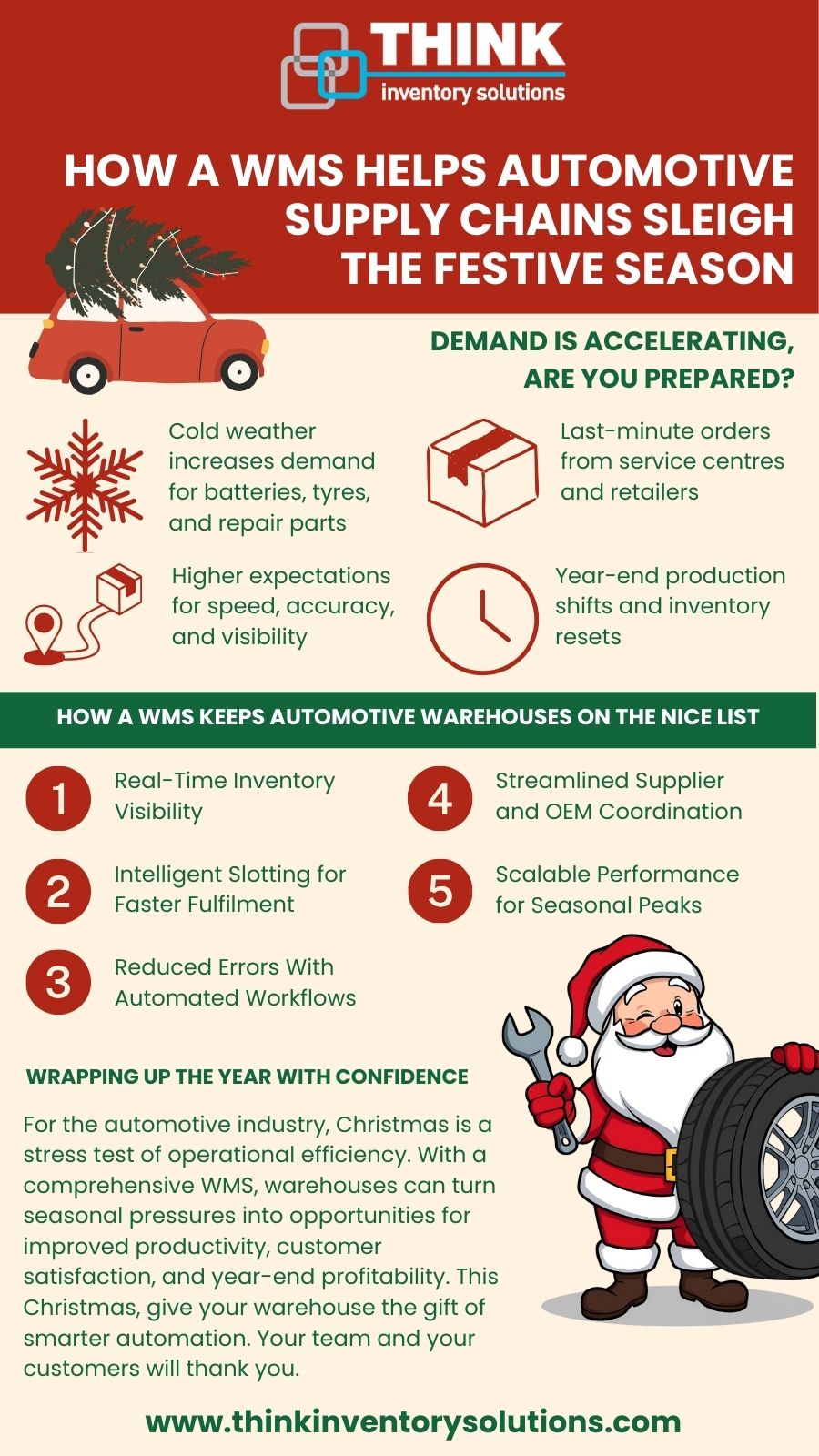

Christmas doesn’t just bring festive cheer; it also brings one of the most demanding periods for the automotive supply chain. From surges in aftermarket parts orders to the year-end push for OEM distribution, automotive warehouses need to run like a finely tuned engine. Yet many facilities still struggle with bottlenecks, backorders, and outdated processes that can turn the “most wonderful time of the year” into a logistical headache. That’s where a THINK Warehouse Management System (WMS) becomes the ultimate workshop helper, think of it as the automotive industry’s very own digital elf. December brings unique challenges to automotive supply chains:

- Cold weather increases demand for batteries, tyres, and repair parts

- Last-minute orders from service centres and retailers

- Higher expectations for speed, accuracy, and visibility

- Year-end production shifts and inventory resets

A WMS helps warehouses stay ahead of these challenges by ensuring that every component, from alternators to air filters, moves through the warehouse with precision and speed.

How a WMS Keeps Automotive Warehouses on the Nice List

Real-Time Inventory Visibility

No more scrambling to locate critical parts, a WMS gives teams instant insight into part availability, locations, and reorder alerts.

Intelligent Slotting for Faster Fulfilment

High-demand seasonal items are automatically prioritised for optimal placement, reducing travel time and boosting picker productivity.

Reduced Errors with Automated Workflows

From VIN-specific components to serialised inventory, accuracy is essential. A WMS eliminates guesswork and manual errors through integrated scanning, guided picking, and quality checks.

Streamlined Supplier and OEM Coordination

Christmas chaos becomes manageable with centralised order, shipment, and supplier data. This ensures deliveries stay on schedule even when roads and schedules are unpredictable.

Scalable Performance for Seasonal Peaks

Whether order volume doubles or triples, the right WMS scales effortlessly, no elves required!

Wrapping Up the Year with Confidence

For the automotive industry, Christmas is a stress test of operational efficiency. With a comprehensive WMS, warehouses can turn seasonal pressures into opportunities for improved productivity, customer satisfaction, and year-end profitability. This Christmas, give your warehouse the gift of smarter automation. Your team and your customers will thank you.

Recent Comments