The automotive industry is undergoing a significant transformation. Sustainability expectations across the UK and EU are increasing, placing new pressure on suppliers to operate more efficiently, reduce environmental impact, and improve transparency across their operations. While regulatory frameworks continue to evolve, the real challenge for most warehouses is building the operational structure, data accuracy, and reporting capability needed to support compliance.

With many years experience supporting automotive suppliers, THINK has seen a clear shift and sustainability is no longer just a regulatory topic, it’s an operational one. Warehousing performance, process design, and data visibility now play a central role in how organisations respond to environmental expectations.

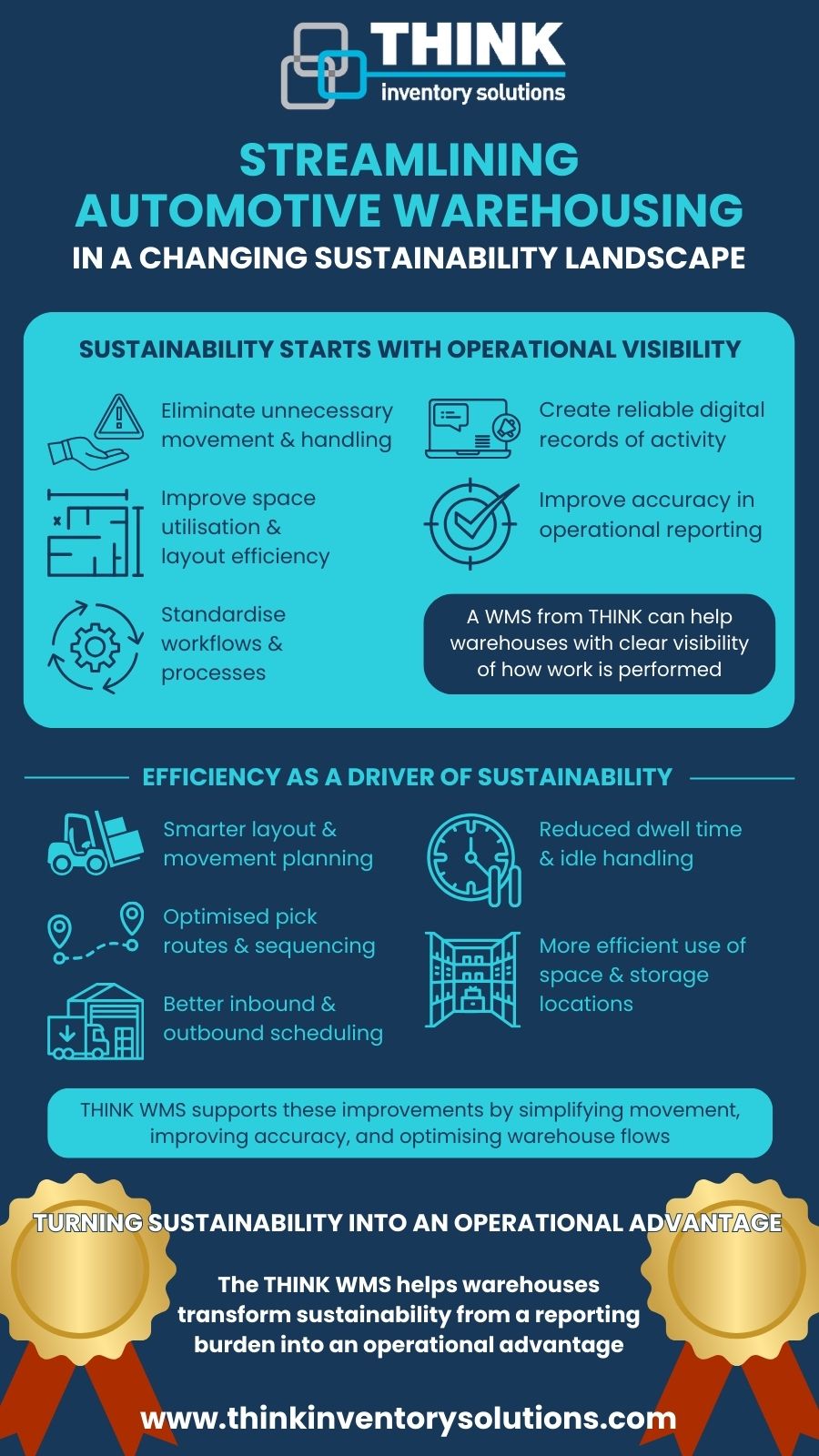

Sustainability Starts with Operational Visibility

As sustainability reporting expands across supply chains, warehouses are increasingly expected to demonstrate control, consistency, and transparency in areas such as energy use, transport activity, waste handling, and process efficiency. Rather than acting as a regulatory system, a modern Warehouse Management System plays a critical enabling role as follows:

- Eliminate unnecessary movement and handling

- Improve space utilisation and layout efficiency

- Standardise workflows and processes

- Create reliable digital records of activity

- Improve accuracy in operational reporting

A Warehouse Management System from THINK can help warehouses with clear visibility of how work is performed, enabling better internal control, stronger reporting foundations, and easier alignment with external sustainability requirements.

Efficiency as a Driver of Sustainability

Sustainability is increasingly being achieved through better operational design rather than standalone environmental initiatives. Automotive warehouses are optimising how products move through facilities to reduce waste, energy usage, and inefficiency. This includes:

- Smarter layout and movement planning to reduce travel distances

- Optimised pick routes and sequencing

- Better inbound and outbound scheduling

- Reduced dwell time and idle handling

- More efficient use of space and storage locations

The THINK WMS supports these improvements by simplifying movement planning, improving sequencing accuracy, and optimising warehouse flows, delivering operational efficiency that naturally supports sustainability goals.

Turning Sustainability into an Operational Advantage

For automotive suppliers, sustainability is no longer just a compliance obligation, it’s becoming a competitive differentiator. Organisations that streamline operations, improve visibility, and strengthen reporting capability are better positioned to meet customer expectations, improve efficiency, and adapt to future regulatory change. The THINK WMS helps warehouses transform sustainability from a reporting burden into an operational advantage. If you’re working within the automotive supply chain and want to strengthen operational performance while building a foundation that supports sustainability and compliance, speak to our automotive WMS specialists today. We’ll help you streamline your warehouse operations and prepare for the future efficiently, practically, and sustainably.

Recent Comments